Syngas: energy-rich gas for power applications

What is syngas?

Syngas, also called a synthesis gas, is a mix of molecules containing hydrogen, methane, carbon monoxide, carbon dioxide, water vapours, as well as other hydrocarbons and condensable compounds.It is a majority product of high temperature pyrolysis carried on any biomass, residues and waste.When produced in pyrolysis, it is created by the vaporisation of volatile compounds from the raw material thanks to the heat, which induces a set of complex reactions.

Consistent generation of syngas fuels

The chemical composition of syngas and proportion of its molecules is highly dependent on the raw material characteristics and conditions of the treatment process. Biogreen technology allows a consistent generation of syngas fuels thanks to the stable, repeatable treatment conditions and possibility of adapting the processing temperature according to the demand.

Syngas from pyrolysis

High temperature pyrolysis process carried in the absence of oxygen results in production of calorific syngas at exceptional heating values, up to even 36 MJ/Nm3. The most energy-rich gases are obtained from the raw materials featuring high calorific values – plastics, polymers, calorific fractions of municipal waste.

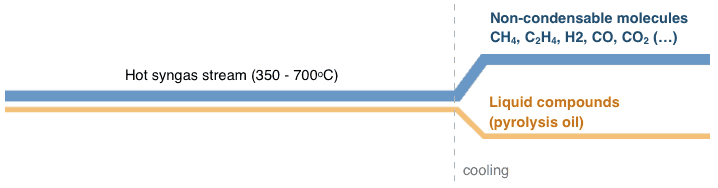

Generated synthetic gas leaving the Biogreen reactor is a hot mixture of condensable and non-condensable phases. The composition of such blend depends on source material (feedstock) and pyrolysis operating conditions. Gases from pyrolysis typically contain significant quantities of methane, hydrogen, carbon monoxide, and dioxide, as well as higher hydrocarbons that build their calorific value and make them important fuel for the chemical and energy industries.

Example composition of syngas compositions from different raw materials

Received syngas composition is strongly dependent on several factors, including the properties of treated material, temperature of process, applied residence time and physical structure of raw feedstock, for details, see chapter What influences pyrolysis process results? Below we provided an example compositions of non-condensable fractions of gases measured at ambient temperature.

| % Vol | H2 | CH4 | C2-C4 | CO | CO2 | N2 | LHV [MJ/Nm3] | kWh/tonne inlet |

|---|---|---|---|---|---|---|---|---|

| RDF | 16% | 25% | 24% | 18% | 15% | 2% | 27.3 | 4690 |

| biomass | 15% | 26% | 3% | 35% | 17% | 4% | 17.10 | 2600 |

| plastics | 25% | 38% | 18% | 9% | 5% | 5% | 28 | 7800 |

| tires | 19% | 40% | 28% | 3.5% | 6.5% | 3% | 36 | 3300 |

Power generation from syngas

The main application of produced syngas is typically the generation of power and heat. This can be realised either in stand-alone combined heat and power (CHP) plants or through co-firing of the product gas in large-scale power plants.

Syngas from pyrolysis is a combustible gas and can be used for the production of power in many types of equipment, from steam cycles through gas engines and turbines. While the usages in boilers for steam cycles typically do not require extensive gas treatment before the power generation, the gas engines request a higher degree of purification and preparation.

The stability and consistency of fuel provided to the internal combustion engine is one of the key factors of process. It is ensured by feedstock stability and the precisely controlled treatment conditions in Biogreen pyrolysis unit.ent temperature

Synthetic natural gas production (SNG)

The high-temperature processes of pyrolysis allow to create significant quantities of syngas with notable concentrations of carbon monoxide, hydrogen and methane. The interest in production of synthetic natural gas through the methanation of H2 and CO is increasing fast.

Following this interest, ETIA partners with European leader in gas transportation systems, GRTgaz. The objective of alliance is construction of a pilot plant dedicated to produce the synthetic methane from waste and biogenic resources.

Proposed plant will combine the leading-edge technologies for high temperature pyrolysis (Biogreen©), gas purification and methanation processes and validate the opportunity of injecting synthetic methane into transmission grid. Technology is based on Synthane©, patented ETIA thermochemical process, developed with support of Banque Publique d’Investissement (BPI) France.

Equipment for syngas production

Biogreen is pyrolysis equipment suitable for production of calorific syngas for all the applications described below. The patented, electrically heated reactor allows to achieve continuous, repeatable conditions of treatment and stable production of syngas. Thanks to the precise control of the carried process and multiple industrial references, Biogreen remains a first choice of customers looking for consistent and reliable production.

Summary of syngas utilisation routes

Directions of hot syngas utilisation:

- heat production for drying or industrial purposes

- industrial steam or thermal oil production

- replacement of conventional fuel in the existing boilers

- electricity generation via ORC turbine

- electricity generation via steam turbine

Directions of ambient temperature syngas utilisation:

- electricity generation via internal combustion engine

- electricity generation via gas turbine

- methane to grid production

- hydrogen production

- fuel cells utilisation

- other special applications

Applications focused on using ambient temperature synthetic gas are linked with necessity of cooling down the syngas and extraction of liquid phase – pyrolysis oil. Electricity generation through internal combustion engine, or molecules separation, requires high degree of syngas purity. Process of cooling pyrolysis gas and separating condensable and non-condensable phases requires additional energy to reduce the managed stream temperatures. As a result, syngas at ambient temperatures is also easier to transport and offers wider scope of perspectives for its further treatment, allowing separation of molecules and their further utilisation.