Tyre pyrolysis: sustainable waste tires and rubber valorisation

Applications & results

Are you interested in end of life tires valorisation?

You can contact us through the website or by filling out the dedicated request for quotation form.

Creating valuable products

In many places used tires are seen as a problematic waste material difficult to get rid of. Biogreen® technology meets the demand of local processing of rubber from used tires and creating valuable products from the pyrolysis conversion.

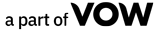

Once the tires have been shredded and separated from metals, the crumbed rubber can be processed in the Biogreen® pyrolysis process to generate high energy syngas, oil and char.

What is reCB (recycled / recovered carbon black)?

Recovered carbon black is a material obtained from solid product of tyre pyrolysis process. Treatment allow it to develop many useful properties that make reCB high added value product that can be considered a filler for the rubber industry, paints and coatings, ink production, and many other industrial applications.

Recycled carbon black produced in tire pyrolysis becomes increasingly popular, environmental friendly alternative to carbon black obtained from oil-based processes.

Example results

| Biogreen Oil | Recycled Carbon Black | |

|---|---|---|

| Yield (w/w) of inlet | Up to 40% | 44% |

| LHV (GJ/ton) | 39 | 30 |

| Density | 0,960 | 0,38 |

| Ashes | 0,051% | 19,2% |

| C | 85,7% | 78% |

| H | 9,8% | 1,26% |

| O | 3,6% | |

| N | 0,6% | 0,31% |

| S | 0,978% | 2,8% |

| Cl | 0,024% | 760 ppm |

| Flash point | 84°C | |

| Viscosity @ 20°C | 11,91 mm2/s | - |

| Viscosity @ 20°C | 4,48 mm2/s | - |

| BET | - | 40 m2/g |