Biochar – turn waste into value

Interested in producing biochar?

Find out about our industrial equipment by sending a request.

One step further

Today there are numerous technologies to reduce our carbon foot print or even make us carbon neutral. The biochar process takes it one step further – it is carbon negative.

It all comes down to how we choose to see the things around us. If we consider it an asset, it holds a value. If not, we call it waste. And one of the biggest challenges we are facing is the ever-increasing amount of waste on land and in our oceans.

At ETIA we can change that today, as we have the means to turn waste into value. Thanks to our Biogreen technology we can offer our customers efficient ways to valorise their feedstock. Whether it is crops, biomass, petroleum residues, and other carbonaceous wastes, our solution will turn it into energy, gas and sustainable soil enhancement. Either to be used by the company itself, or sold on the open market.

What is biochar?

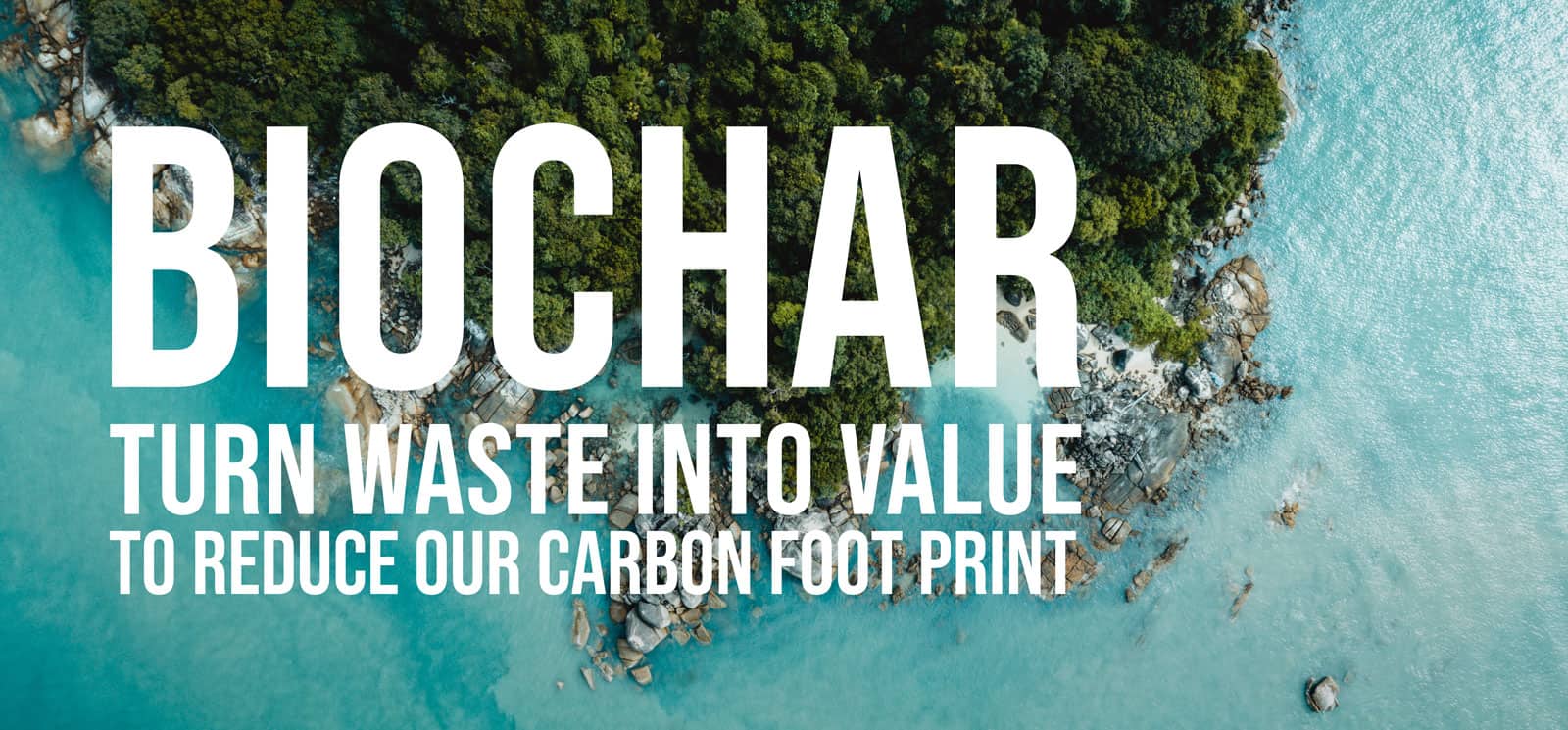

Biochar and biocoal are terms that most of us are familiar with, but what exactly is biochar? As a product, biochar differs from biocoal, which is produced at lower temperatures and considered as solid fuel, containing high quantity of volatile matter and lower fix carbon than biochar.

– Because of higher process temperatures, the chemical structure of biomass changes and content of hydrogen, nitrogen and organic carbon in biochar is significantly decreased when fix carbon concentration increase. In contrary to charcoal, biochar is also not phytotoxic.

Biochar is mainly used in agriculture to enhance soil fertility and water retention capacity and then improve plant growth. As a result, it improves the overall farming productivity. But biochar can also be used in animal feed or as a bio-based substitute of active carbon.

State-of-the-art technology

Protected by international patents the Biogreen technology is a robust, reliable and cost-efficient process, allowing for very precise operating conditions up to 1000°C.

In addition, thanks to having an electrically heated spiral, the Spirajoule allows the user to adjust both the process time and temperature – two essential pyrolysis parameters to control, in order to achieve the desired quality of biocoal, biochar and other products.

Processed bulk products, after entering the pyrolysis chamber, is efficiently conveyed along the reactor and transformed by temperature in the pyrolysis chamber.

The Biogreen operating parameters are easily adjusted, allowing for optimal treatment conditions for each individual particle. These features make Biogreen a reliable solution that adapts to the process conditions and guarantees a constant quality of the production.

Climate impacts

When biomass is deteriorating or burned, a significant quantity of carbon dioxide is released into the atmosphere and contributes to the negative climate impacts. This could be avoided when producing biochar instead. Biochar becomes one of the best solutions for carbon sequestration.

When biomass is subjected to the pyrolysis process in our Biogreen process, the majority of carbon remains in the solid product, together with the minerals and most nutrients. Not only does biochar help to reduce the amount of carbon dioxide released into the atmosphere, but simultaneously it’s also creating an extremely efficient soil additive that needs no chemical adjustments.

During the production of biochar, the pyrolysis gases are considered as an energy source and help to reduce dependency on fossil fuels. This allows to reduce the overall fossil fuel consumptions and can represent a sustainable approach to reduce the greenhouse gases emissions in developed countries Pyrolysis gas can also be upgraded to produce methane or hydrogen.

Amazon Indians

Biochar is a perfect example of the old saying; taking a step back can be the best way forward. The biochar history traces back to an ancient method of Amazon Indians, used to change infertile, sandy soils into rich and sustainable fields, also noticed as distinctive dark-colored soils called terra preta. The carried analysis showed that these types of earth are much more fertile than other soils in the Amazon basin thanks to the presence of a special type of charcoal, which was later named biochar.

This special ingredient has been scientifically dated hundreds to thousands of years ago as an exceptionally stable soil improver. Today, the biochar added values are more and more often explored in the industrial scale, allowing to generate this natural soil nutrient by safe, low-emitting and resource efficient technologies.

Biochar is the only effective way that we know of, to actually remove CO2 from the atmosphere.

Our technology offers a unique possibility to decarbonize the industry by turning waste and residues into value. We can be the generation that turned the tide and that is something we want to be a part of.

The biochar markets

- soil additive: water retention product (Hydrochar)

- soil conditioner: nutrients carrier

- soil remediation assistant

- precursor for activated carbon

- filtration / decontamination material

Are you looking for equipment to produce biochar? Do not hesitate to contact us.